To adjust the carburetor on your chainsaw, follow these steps:

- Place the chainsaw on a flat surface and turn off the engine.

- Locate the air “L” and fuel “H” regulators. They are typically found on or near the carburetor.

- “L” for low-speed adjustments;

- “H” for high-speed adjustments;

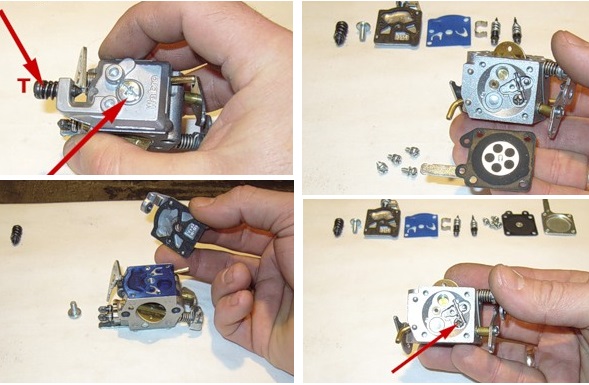

- “T” for idle adjustments (models with a single screw only have this).

- Fully loosen the air and fuel regulators.

- Start the engine and let it run at high speeds for 5-20 seconds.

- Gradually close the “T” air screw until the engine begins to stall.

Open the air regulator slightly and slowly close the fuel regulator until the engine operates smoothly.

Ensure the engine runs properly without any power or performance issues.

If the engine is unstable, return to step 5 and repeat the adjustment procedure.

Check the fuel level in the tank. If the fuel depletes too quickly, inspect the fuel system’s seals for leaks.

L and H Screws

- “L” for low-speed adjustments;

- “H” for high-speed adjustments;

- “T” for idle adjustments (models with a single screw only have this).

What Do the L and H Letters on a Chainsaw Mean? Adjusting with L and H Screws.

To increase the speed, turn them clockwise.

To decrease the speed, turn them counterclockwise.

The screws should be turned in this order: L – H – T.

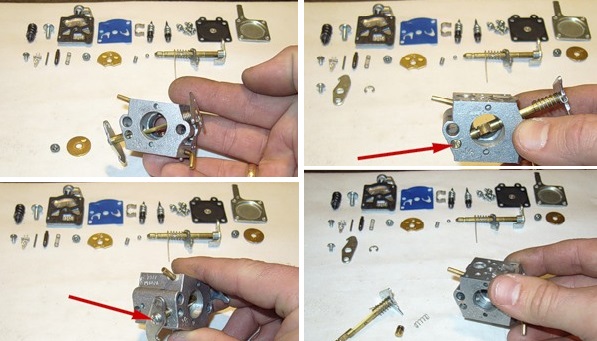

Step-by-Step Carburetor Disassembly

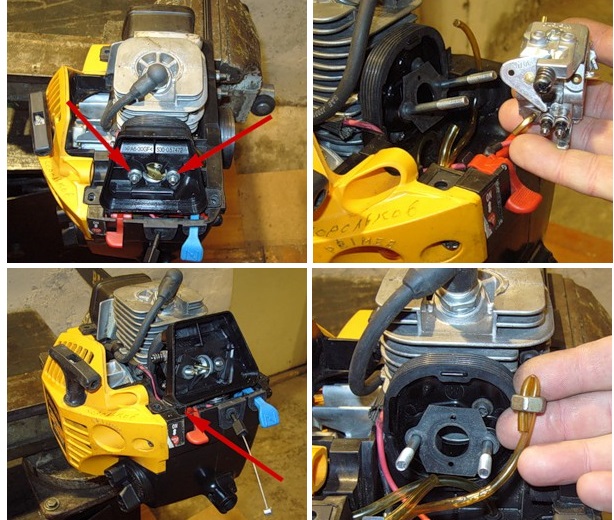

The process of disassembling the carburetor plays a significant role in its adjustment. As carburetors in different chainsaws do not fundamentally differ from each other, let’s consider the disassembly of a Partner chainsaw. All elements should be carefully removed and laid out to facilitate the subsequent reassembly process.

Remove the top cover by unscrewing three bolts. Then, remove the foam component in the air filter as shown in the image with red markers.

Next, remove the fuel hose and the drive linkage. The upper marker indicates the fuel supply hose, and the arrow points to the end of the cable, which needs to be removed.

On the left side, proceed with the removal of the gasoline hose.

The Structure of a Chainsaw Carburetor

The carburetor in a chainsaw is an essential component responsible for regulating the air and fuel mixture entering the engine. The device consists of the following components:

- Carburetor: It has two parts – the upper and lower sections. The upper part contains the vent channel, allowing air into the engine. The lower part contains the fuel regulator, managing the amount of fuel entering the engine. The fuel regulator operates based on the lever position and air intake into the engine.

- Air Filter: It filters out contaminated or dusty air to ensure efficient engine operation.

- Control Lever: It allows the operator to adjust the air and fuel ratio.

The carburetor is a crucial device ensuring the correct delivery of fuel and air to the engine. It must be regularly adjusted and checked for functionality to ensure the smooth operation of the chainsaw.

The carburetor is one of the most critical components of the engine. It prepares and supplies the fuel mixture, consisting of combustible material and air. If the air and combustible ratio is disrupted, the engine’s performance deteriorates, and it may even stall. To ensure the carburetor functions correctly, it’s essential to know its components:

- A tube with a cross flap to regulate the airflow.

- A diffuser – a constriction that increases the speed of the airflow, located near the fuel inlet.

- A sprayer, which serves to supply fuel (indicated in the diagram as a fuel needle).

- A float chamber, where the fuel level is regulated at the inlet channel.

- A diagram illustrating the interaction process between the fuel and airflow.

Description of the operating principle: The fuel is atomized by an air jet in the diffuser area, creating a mixture that enters the cylinder chamber. As the amount of fuel supplied increases, the engine’s RPM also increases. The operation of various carburetors follows the same principle.