Spot welding was invented almost 90 years ago, and its possibilities are far from exhausted. This type of welding is primarily used for mass or serial production. To further develop this technology, a transition to mechanized and automated mass production with serious electrification is required. However, many industrial sectors cannot boast of such conditions. Below, we will take a closer look at how to do spot welding at home.

Understanding Spot Welding

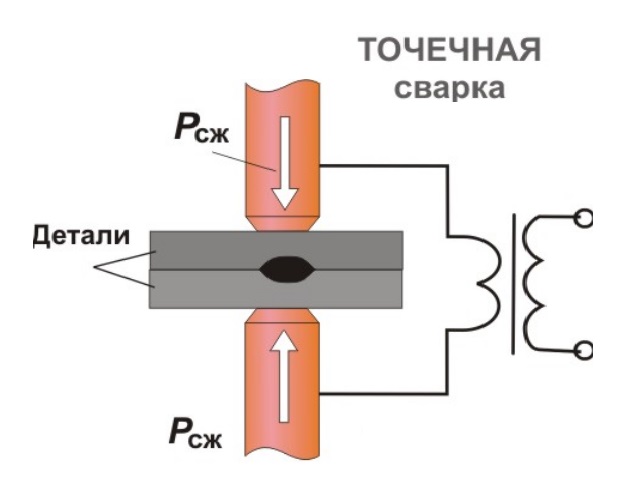

Spot welding is a step-down transformer with a high transformation ratio.

The welding current must be very high. The thicker the metal being welded, the greater the current strength required for the transformer’s secondary winding. At the same time, the required voltage (U = JR) should be low, within the range of 2-6 V.

This is because metallic objects have high electrical conductivity and low specific resistance. To quickly heat the metal and compensate for heat losses, large welding currents need to be used. To obtain a welding current with such unusual parameters, a special power source is required – a transformer with sufficient power.

DIY spot welding is a realistic task, provided that the metal being joined is not thick (no more than 0.5 mm thick). This device can be made at home using readily available materials.

To build this device, you can use a MOT (microwave oven transformer) with a power rating of 1000 W.

If you have such a transformer, consider half of the project already completed. In addition to the transformer, you will need the following components:

- Wooden bars

- Two copper screw terminals

- Two copper terminals

- Welding cable for the secondary winding (preferably thicker)

- Galvanized angle brackets

- Self-tapping screws

- Washers

First, remove the secondary winding initially wound on the transformer. An angle grinder will be helpful in performing this task.

After that, wind the secondary winding using welding cable to make our transformer a step-down transformer. Through experimentation, it was determined that three to four turns are sufficient to provide a voltage of 4-5 V.

The most challenging part is already behind us. After mounting on a wooden base and equipping wooden clamps, your DIY spot welding device can be considered complete.

Video Tutorial: DIY Spot Welding

By following these steps, you can create a spot welding machine at home, enabling you to join metal pieces effectively. It’s a cost-effective solution for small-scale welding projects.